Tesla has applied to get government support for a series of 9 megacharging stations from California to Texas.

Tesla-Owned or Operated Megacharging Installations

These are primarily at Tesla’s Gigafactories for testing and production support:

Giga Nevada (Sparks, NV): Early Megachargers installed as far back as 2021 for Semi prototyping and testing. Expanded for ongoing operations.

Giga Texas (Austin, TX): New Semi Megacharger added in May 2025 to support increased Semi production and testing.

Carson, CA (19300 S Hamilton Ave): Tesla’s first “public” Megacharger site, with construction permits filed in February 2025. Located near the 405 and 110 freeways and the Port of Long Beach.

As of mid-2025, it includes up to 12 stalls for Class 8 vehicles like the Semi. This site is operational for limited use, marking Tesla’s initial step toward public access.

Planned Megacharging and Depot Charging Through End of 2026

Tesla’s plans emphasize scaling for Semi volume production, which is set to ramp up in late 2025 and hit full scale (up to 50,000 units annually) in 2026. This includes a dedicated public Megacharger network along major freight corridors, plus expanded depot charging for customers.

Announcements from April-May 2025 (e.g., at ACT Expo) outline the following:

Public Megacharger Network Expansion

46 New Megacharger Stations: Tesla is developing a public network with 46 initial locations, expected to be operational by early 2027. Construction is underway across major U.S. freight corridors (e.g., between California and Texas). Through 2026, expect progressive rollout:

Initial focus on 9 stations from California to Texas (e.g., along I-10 and I-5 corridors).

Sites will include high-power stalls (1-1.2 MW) integrated with solar and Megapack batteries for off-grid capability.

First full-scale sites beyond Carson, CA, targeted for completion in 2026, with others following.

Timeline: Equipment landing and site setup throughout 2025-2026, with volume deployment ramping in 2026 to support Semi production scale-up.

Customer-Owned Depot Megacharging Installations

Tesla customers, particularly early Semi adopters, have installed Megachargers at their depots for fleet charging. These are often co-developed with Tesla and powered by on-site solar or grid connections

PepsiCo/Frito-Lay Facility, Modesto, CA: Initial depot charging installed in late 2022 for PepsiCo’s early Semi fleet (first deliveries in December 2022). Expanded by 2025 to support additional trucks.

PepsiCo/Frito-Lay Facility, Charlotte, NC: Major Megacharger hub installed in July 2025, with 18 stalls each delivering up to 1 MW. Supports rapid charging to 70% in about 30 minutes for Semi trucks.

PepsiCo Facility, Denver, CO: Expansion of Semi charging infrastructure added in July 2025, including multiple Megacharger stalls for depot operations.

Livermore Distribution Center, CA: Tesla Semi chargers (likely Megachargers) installed by May 2025, potentially for Tesla’s own logistics or partner use.

Customer Depot Charging Expansions

As Semi deliveries increase in 2026, Tesla anticipates more customer installations similar to PepsiCo’s.

Plans include:Custom depot setups for new Semi fleets, emphasizing slow overnight charging (to minimize costs) combined with on-route Megachargers.

Integration with Tesla’s energy products (e.g., Megapacks for energy storage) at depots in states like California, Texas, and North Carolina.

Potential expansions at existing customer sites (e.g., further PepsiCo locations) and new adopters, driven by Semi orders.

Key Enablers and Broader Plans

Battery and Tech Upgrades: New 4680 cells and e-PTO (electric power take-off) systems announced in 2025 will enable faster charging and better efficiency, supporting network growth.

Geographic Focus: Primarily U.S.-centric (major highways like I-405, I-110, I-10), with potential for Europe if Semi expands there.

Regulatory and Incentive Ties: Plans align with U.S. incentives (e.g., IRA-compliant cells) and state programs for EV trucking infrastructure.

Challenges: Rollout depends on permitting and grid capacity; Tesla emphasizes solar + battery integration to mitigate this.

Compatibility and Effectiveness of Tesla Semi Using Superchargers

The Tesla Semi is primarily designed for high-power Megachargers (up to 1.2 MW with V4 hardware), which allow for rapid range top-offs, such as adding 400 miles in about 30 minutes.

However, it can use regular Tesla Superchargers for charging, though this is not the optimal or intended method for operational use. Here’s a breakdown based on available data:Compatibility

Connector and Setup: The Semi uses a proprietary high-power connector for Megachargers, but for Superchargers, Tesla has employed a custom “extension cord” system that connects to multiple Supercharger stalls simultaneously. This bundles power from several V3 (250 kW max) or V4 stalls into the Semi’s charging ports. Early prototypes were spotted using this setup during cross-country testing as far back as 2018.

Voltage and Power Handling: Superchargers operate at around 400-500V, while the Semi’s battery is optimized for 800-1000V systems. V4 Superchargers (rolling out in 2025) support up to 1000V and 1.2 MW for the Semi, making them more compatible. Older V3 stations limit the Semi to lower effective power.

Current Status (as of August 2025): Tesla Semis have been observed charging at Superchargers during testing and limited fleet operations (e.g., PepsiCo fleets). However, this is mostly for emergencies or short top-offs, not routine use. The Semi’s software and hardware are compatible, but public access is restricted—fleet operators coordinate with Tesla.

Charging Speeds:V3 Superchargers (250 kW max): Using multiple stalls (e.g., 4-8), effective power can reach 500-1000 kW in theory, but practically it’s around 300-600 kW due to limitations. Adding 200 miles (~300 kWh) takes 30-60 minutes if bundled; single stall would take 1-2 hours. This is slow for trucking needs and ties up multiple stalls.

V4 Superchargers (500 kW for EVs, up to 1.2 MW for Semi): Much better—can deliver megawatt-level charging with the right cable. Adding 400 miles could take under 30 minutes. V4 cabinets (deploying in 2025) support this, but as of now, they’re limited to select sites.

With V4 rollout, compatibility improves significantly. Tesla’s Dan Priestley noted immersion-cooled cables enable 1+ MW without bulky hardware, making Superchargers more viable for Semi.

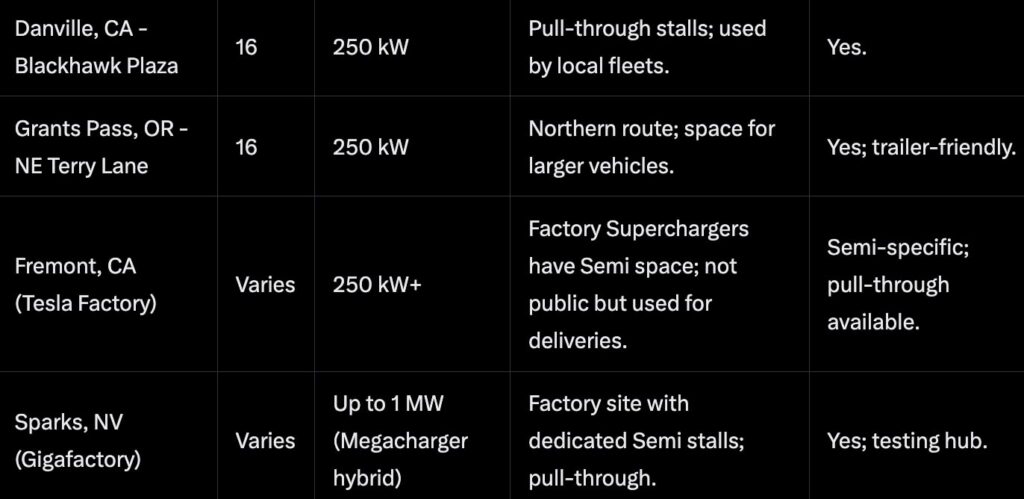

Supercharger Locations with Room for Tesla Semi TrucksMost Supercharger stalls are back-in designs for cars, not accommodating the Semi’s size (up to 70-80 feet with trailer). However, Tesla marks “trailer-friendly” sites in the app—these have pull-through stalls, wider spaces, or are at truck stops. As of August 2025, there are ~200 trailer-friendly Superchargers globally (mostly U.S.), filtered via the Tesla app or sites like supercharge.info (which has a “trailer-friendly” filter).

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.